World-Class Facilities

Within the five partner institutions of the Center for E3S, a wide range of world-class facilities is available to all members of the Center. To foster collaborations between Center members across institutions, the E3S Student & Postdoc Rotation Program was established. Through this program students and postdocs of the Center can travel to any of the partner institutions for a period of up to nine weeks and use equipment and facilities that is not available at their home institution.

All facilities are managed and maintained by dedicated teams of technical professionals as multi-users facilities with a recharge system. The nanofabrication staff provide process, administrative, safety and software support. Critical equipment and processes are routinely monitored. The results are statistically analyzed and compared to control standards to guarantee that processes and equipment remain in control. Descriptions of the facilities at each institution are given below.

Marvell Nanofabrication Laboratory at UC Berkeley

The Berkeley Marvell Nanofabrication Laboratory (The NanoLab) is a 15,000 sq-ft state-of-the-art clean room facility with a wide range of micro and nanofabrication capabilities for interdisciplinary research, including device electronics, optoelectronics, superconducting devices, micro and nano electromechanical systems and miniaturized integrated sensor platforms.

Among the laboratory’s major features are a computer area for device and circuit layout; a lithography center, which includes an electron beam nanolithography writer, three step-and-repeat reduction cameras (436nm, 365nm and 248nm deep UV), two multi-substrate backside capable contact aligners, and a mask-making facility with an optical pattern generator; thin-film systems; a 4″/6″ silicon wafer processing area equipped with twenty LPCVD and atmospheric furnaces, process-specific plasma etchers, wet processing stations, a wide range of metrology equipment for in-line testing and specialized analytical diagnostics; and a planarization laboratory with chemical-mechanical polish systems. Unique processing capabilities include silicon carbide deposition for harsh environment encapsulation; thin diamond deposition via hot wire CVD; aluminum nitride reactive sputter deposition for piezoelectric thin film applications; atomic layer deposition for formation of sub 5nm high-k gate dielectrics; and, molecular vapor deposition for chemical derivatization of released nanostructures. The facility supports a 0.35 um CMOS baseline process available for demonstrating integration of novel MEMS and electro-optic technologies with underlying CMOS architectures.

Weblink: https://nanolab.berkeley.edu/

Microsystems Technology Laboratories at MIT

MIT’s Microsystems Technology Laboratories (MTL) is a combination of five shared facilities.

Integrated Circuits Laboratory: ICL is a 2800 sq-ft class 10 integrated circuit fabrication facility designed, equipped and staffed to serve as a highly advanced silicon integrated circuit, device, structures, and process research facility. It also has capabilities for processing compound semiconductors. It houses a complete 6 inch silicon IC fabrication line, and ULSI discipline and protocols are maintained throughout. Using a combination of i-line stepper and electron-beam lithography, nanoscale transistors and nanowire FETs have been fabricated in this facility.

Technology Research Laboratory: TRL is a 2200 ft2 class 100 microelectronic fabrication facility that supports the development of flexible semiconductor process and fabrication technologies as well as novel microcircuits and microstructures. Wafer sizes of 6”, 4” and small pieces are accommodated in TRL.

Exploratory Materials Laboratory: EML is a flexible thin film deposition lab, with photolithography, etching and metrology capabilities. It has few limitations, beyond those called for by safety protocols, on substrate and source materials. It consists of 2,000 ft2 class 10,000 clean space.

Electron Beam Lithography Laboratory: EBL is an 800 ft2 class 100 lab which houses an Elionix EFS-125 high-resolution, e-beam writing system, and a He-ion microscope. The e-beam system has excellent overlay accuracy, high throughput and capability for mix-and-match optical/e-beam lithography. It can process wide range of substrates from pieces up to 8” diameter wafers.

NanoStructures Laboratory: NSL develops techniques for fabricating surface structures with feature sizes in the nanometers to micrometers range. It includes 1,000 ft2 class 100 clean space and 1,000 ft2 of class 10,000 and associated support space.

Collectively, these laboratories enable the MTL to provide full capabilities for device fabrication including photolithography, e-beam lithography, thin-film deposition, silicon/germanium/carbon epitaxial growth, III-V semiconductor epitaxial growth, furnaces, rapid thermal processing, plasma etching, chemical-mechanical polishing, electroplating, optical and electron microscopy, thin-film metrology, and packaging. Additionally MTL supports a complement of sophisticated test and measurement equipment for device, circuit and system characterization, as well as modeling and CAD.

The MTL is complemented by the Scanning-Electron-Beam Lithography (SEBL) facility, which enables the writing of patterns of arbitrary geometries with minimum features as fine as 10 nm. The facility has a Raith 150, which is an SEM modified for e-beam lithography and has a maximum operating voltage of 30 keV. Protocols enable transfer of wafers between the SEBL facility and the MTL fabrication facility, so that e-beam lithography can be used in fabricate nanoscale devices in full process flows.

Weblink: https://www.mtl.mit.edu/

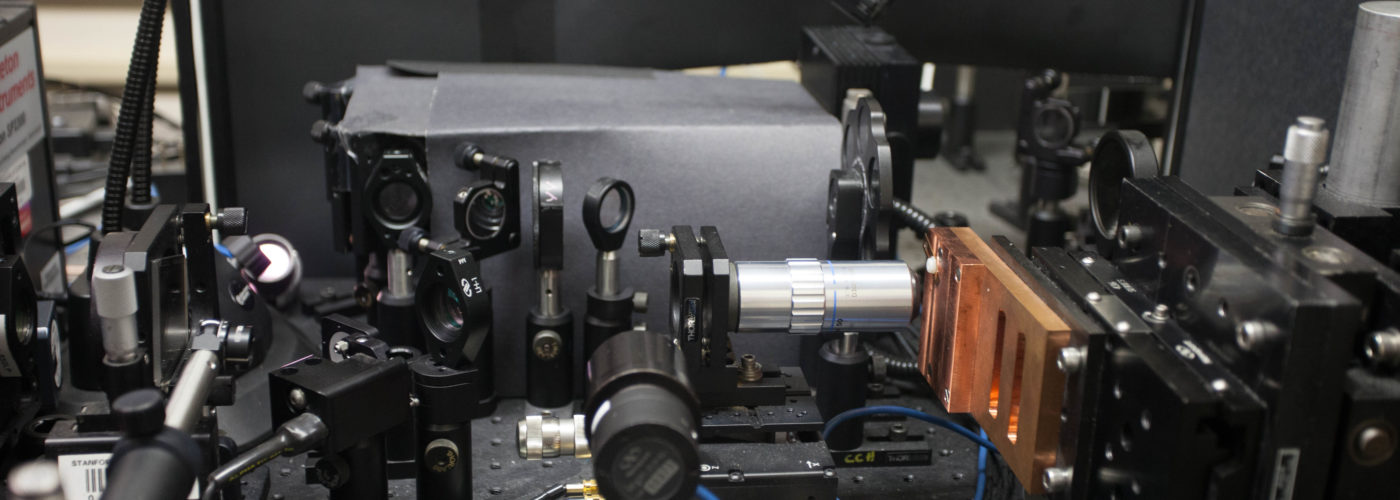

National Nanotechnology Infrastructure Network (NNIN) Node at Stanford

Part of the National Science Foundation funded NNIN, Stanford University’s shared laboratory facilities include the Stanford Nanofabrication Facility (SNF), the Stanford Nanocharacterization Lab (SNL) and the Stanford Nano Center (SNC). More than a lab, the Stanford Nanofabrication Facility is a vibrant research community of academic, industrial, and governmental researchers across the U.S. and around the globe. The facility centers around a 10,000 sq-ft cleanroom equipped with a full suite of tools supporting device fabrication. The Stanford Nano Center includes some of the most advanced nanoscale patterning and characterization equipment available. Its sister facility, the Stanford Nanocharacterization Laboratory, provides modern facilities for the characterization of materials. Collectively, the Stanford node supports MEMS, nanophotonics, biomedical devices, low-temperature experimental physics, and nanoelectronics.

SNF supports deposition, patterning, and etching of new thin film materials. It offers instruments for ALD, GaAs MOCVD, and silicon/germanium epitaxy. SNF enables the building of device structures with feature size as small as 5 nm. There are also capabilities to deposit a wide variety of oxides and metals. The three newly installed atomic layer deposition (ALD) tools enable the deposition of custom thin films.

A 2012 facility upgrade created the SNC, where researchers functionalize and integrate new materials. SNC/SNL offers a JEOL 6300 electron-beam lithography system, a Cameca NanoSIMS 50l, an FEI Helios cryo-FIB/SEM, and an FEI Titan Environmental-TEM with aberration correction. The facilities also include a variety of characterization tools that are typically used to study the composition and surface quality of nanoparticles and thin films after fabrication, such as TEM, SEM, AFM, XRD, XPS, FIB, etc.

Weblink: https://www.nnin.org/

NanoMaterials Integration Lab (NanoMIL) at UTEP

The NanoMaterials Integration Lab (NanoMIL) is a university laboratory that emphasizes academic and professional development while conducting stimulating research. The lab supports and mentors individuals at different stages of their careers from the undergraduate to the professoriate levels in a team environment. Research emphasizes the nanoscale aspects of matter and the application of nanotechnology to create novel materials and devices. Areas of focus are thin-film photovoltaics, memristors and silicon microelectronic processing.

NanoMIL is equipped with a 6,000 sq-ft class-100 nanofabrication facility and more than 20 pieces of major research instrumentation for fabrication and characterization.

The Lab has experienced rapid growth in its level of technology, infrastructure and funding. It enjoys research partnerships with academia, national labs, and industry. The Lab generates multimillion dollars in collaborative research funding. The combination of physical and intellectual infrastructure poises NanoMIL for exciting and continued growth.

Weblink: https://www.utep.edu/orsp/

Advanced Materials Engineering Research Institute at FIU

The Advanced Materials Engineering Research Institute [AMERI] provides an open access equipment infrastructure to support materials research and engineering over a broad range of technology and capabilities. The Institute provides analytical instrumentation, materials characterization, and process development laboratories to support faculty and industry in the development and characterization of new materials over the continuum from the nanoscale to bulk materials.

The Analytical Instrumentation Laboratory contains a field emission scanning electron microscope (FESEM), a 200 keV Transmission Electron Microscope (TEM), Atomic Force Microscope (AFM), X-ray diffraction, thermal (DSC, TGA, DMA, dilatometer flush diffusion, and mechanical testing (uniaxial/biaxial Instron, creep). Process Development laboratories for ceramic processing (sol-gel, tape casting, milling), polymer processing, metal processing, and arc melting, thermal processing (air, vacuum, hydrogen, controlled atmosphere furnaces) are available to support faculty and student researchers.

The Institute contains the Motorola Nanofabrication Research Facilities, which is supported by a class 100 clean room and nanofabrication capabilities including e-beam lithography and optical photolithography. Fabrication of nano/micro electromechanical systems (N/MEMS) can be accomplished by a combination of nanolithography, reactive ion etching, and thin film deposition by a variety of techniques (e-beam, sputtering, filament evaporation, CVD).

Weblink: https://ameri.fiu.edu/